Plating Bone Fractures

In order to aid the healing process of bone fractures, the bone segments can be immobilized by external or internal fixation. The design and material choices for such fixation devices can differ significantly. In some cases, the fixation device is customized to the patient at hand.

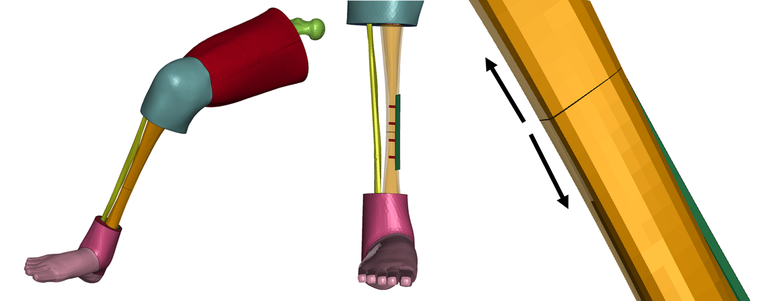

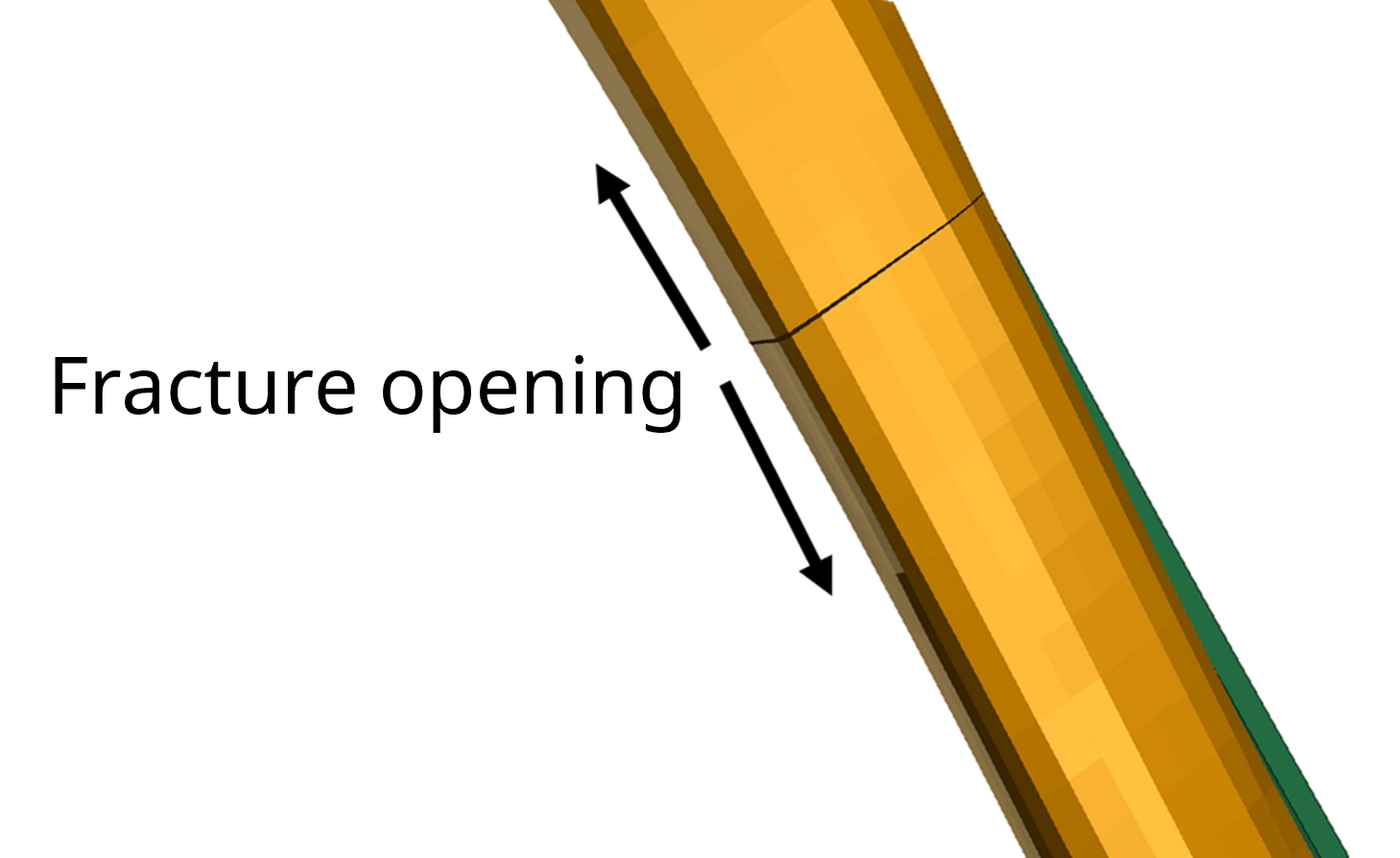

In this case study, a complete fracture is assumed in the tibia shaft. The fracture is immobilized with a steel plate, which is attached to the bone with screws. The performance of the fixation plate is evaluated using LS-DYNA and a leg model obtained from a Human Body Model.

The THUMS model

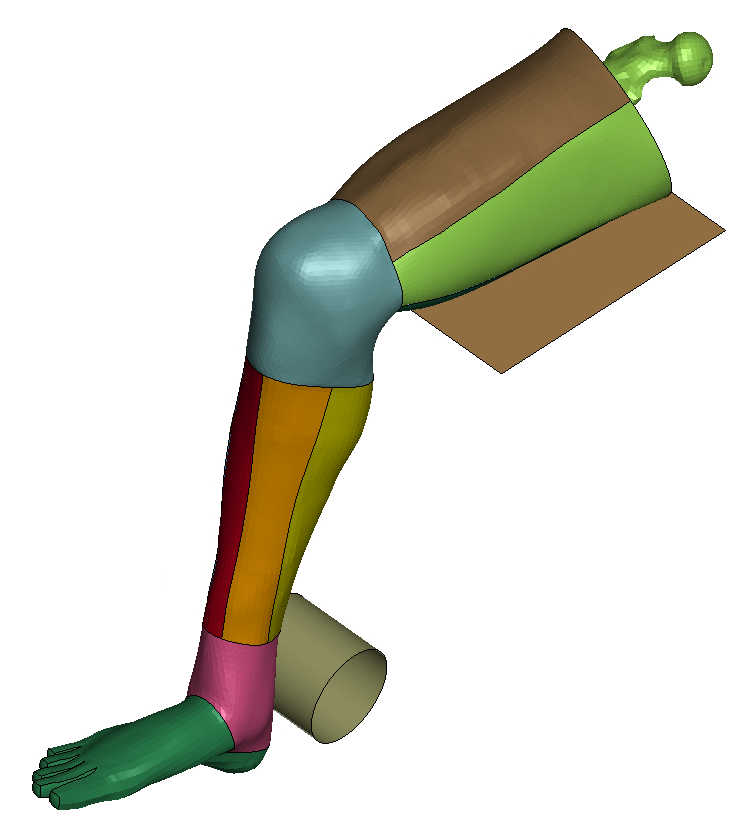

The Total Human Model for Safety (THUMS) is a human body FE-model developed by Toyota. The model is capable of simulating human body injuries, such as bone fracture and damage to the brain and internal organs in e.g. a vehicle crash. In contrast to the ATDs, the material models and geometry of the THUMS are intended to represent the tissue, bones and muscles of a real physical person.

From January 2021, the model is available without a license cost, under some conditions. For more information, contact your local LS-DYNA distributor.

The model is available for different genders, ages and physiques. The present case study is based on THUMS AM50 (v6.1), which represents an average adult male.

Method

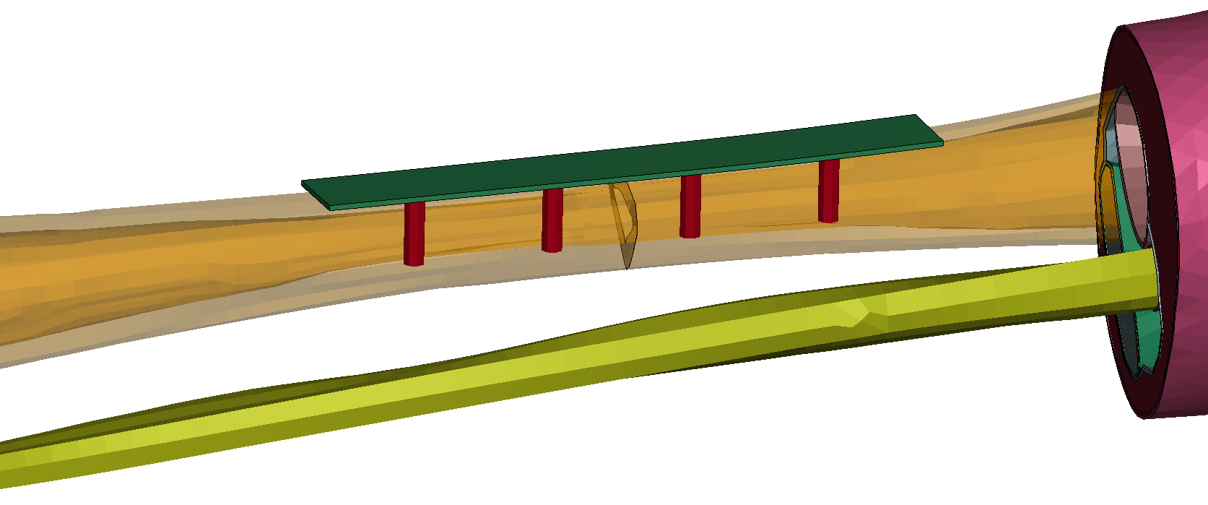

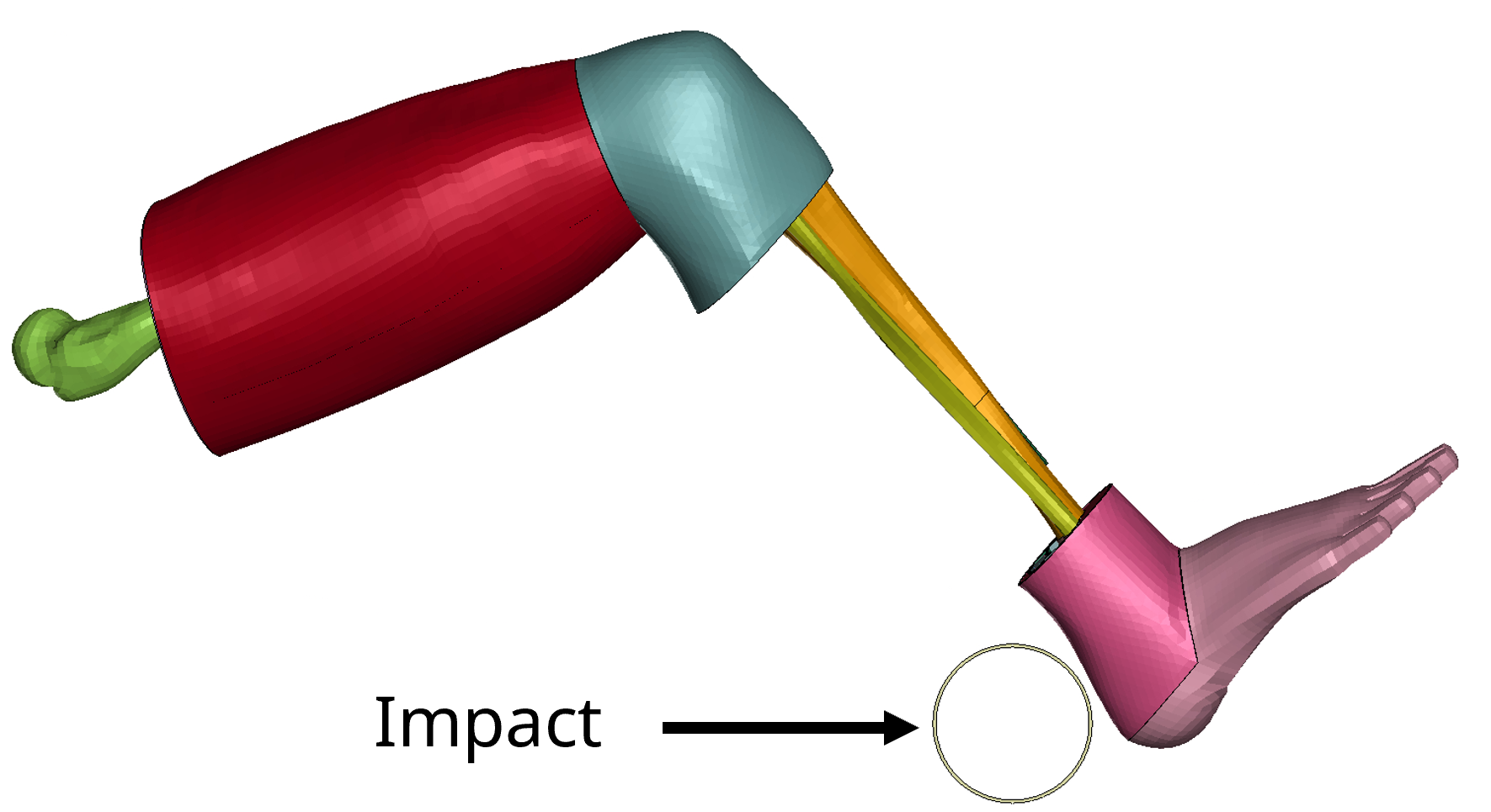

A basic model of a steel fixation plate (shell elements) with screws (beam elements) was developed. The material properties were assumed elastic. The screws were attached to the bone using nodal constraints. The plate was clamped to the bone during dynamic relaxation by prestressing the screws. The leg model was obtained from THUMS AM50 (v6.1). All active muscles were removed to simplify the model further since they were deemed not relevant for the case. The load condition was an impact on the heel. The objective was to minimize the opening between the fractured surfaces when subjected to the dynamic load.

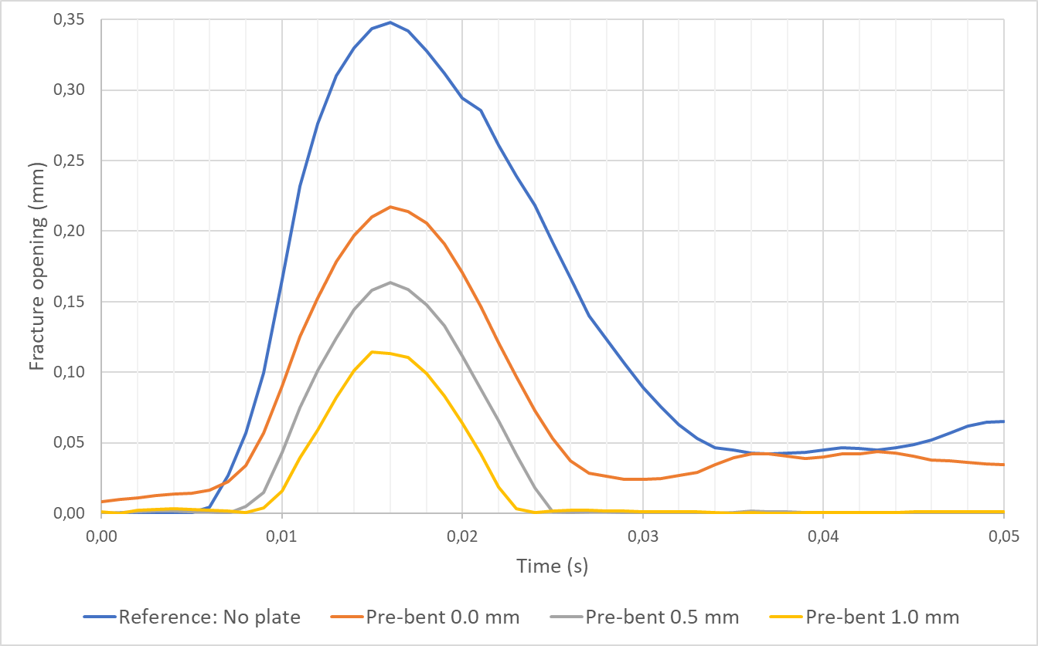

The analyses were performed using the explicit mechanical solver of LS-DYNA (mpp s R12.1). The problem time was 0.05 s, and the solution time was about 40 minutes on 20 cores.

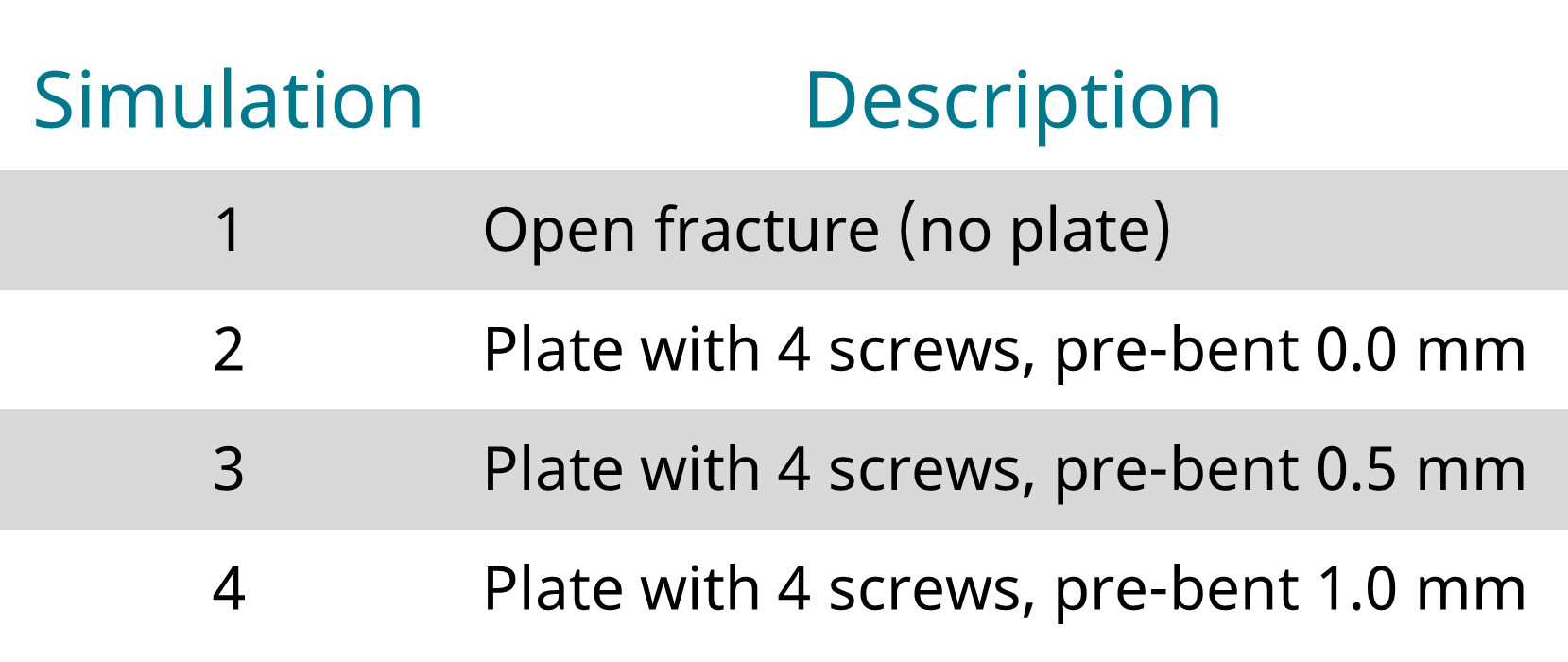

Method - prestress

For reference, an initial simulation was performed without a fixation plate included. Then three simulations were performed with the plate included. The plate was attached with four screws in all simulations; however, the geometry of the plates differed slightly. The plate variants were a straight plate (pre-bent 0.0 mm), a plate that was pre-bent 0.5 mm, and a plate that was pre-bent 1.0 mm. The pre-bent plate had an initial play between plate and bone. This play was reduced to zero when prestressing the screws. The compression forces that were built up through this manner may be beneficial for the performance of the fixation. Let's find out!

Results

The maximum fracture opening was reduced from 0.35 mm to 0.11 mm by the use of a fixation plate. A pre-bent plate was shown to be beneficial, both in terms of reducing the maximum fracture opening, but also note that the fracture opening before and after the impact is zero.

Reference simulation: No plate

Plate pre-bent 1.0 mm

In conclusion

The development of HBMs, based on geometry and material data from physical humans, opens for new analysis possibilities within biomechanics. In the present case study, the highly advanced THUMS model, originally developed for injury assessment of the human body in vehicle collisions, was used in a study of orthopedic fixation devices.

In this case only the leg of the HBM was used. The model was further simplified by removing all active muscles. The end results was a fast model that allow quick turn-around times for evaluation and optimization.

A similar approach as demonstrated in this case study can probably be used for evaluation and optimization of a variety of design parameters , such as for instance:

- Screws

- Numbers, quality, length, positioning, pretension etc.

- Plate

- Geometry, material, pre-bend, positioning etc.

- Bone

- Size and strength etc.

To learn more

Simulations have time and again proven to be a cost-effective product development tool that avoids costly tooling redesign. We have the software and knowledge required so that you may learn to perform these simulations yourself. We will guide you all the way, including training and support. To learn more, please contact one of our technical experts listed on this page.